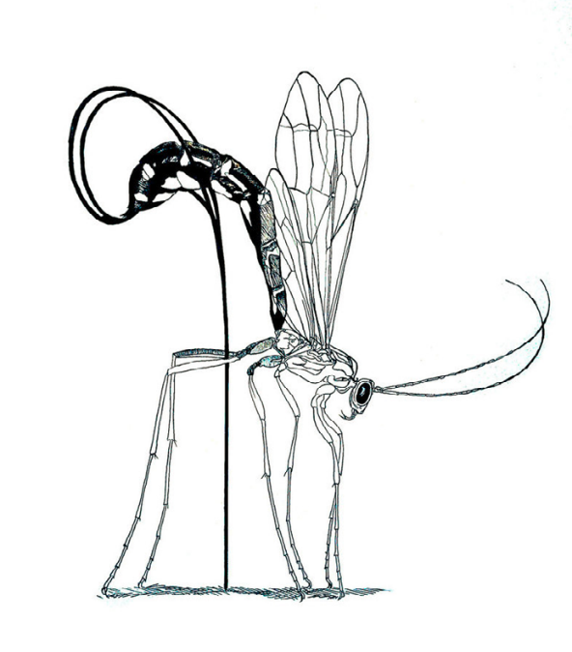

Inspired by Nature

Wood wasps use a special non-rotational drilling technique

Holes are rasped deeply into the wood by their Ovipositor in order to lay eggs into the tree

The process requires almost no axial force and torque

The wasp‘s Ovipositor consists of three parts that move cyclically in a pendulum stroke movement to rasp off wood

This complex process was abstracted and covered in detail in our patents.

Unique Features

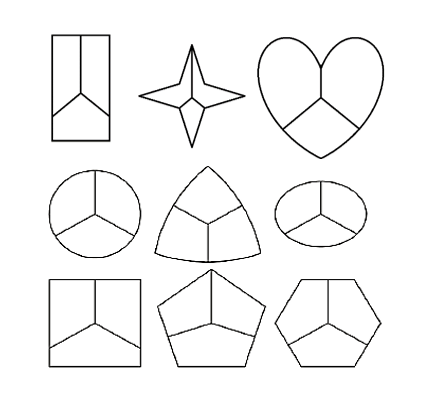

Almost any shape of hole can be made in most materials |

No roll up and pull out of fibrous materials |

Holes are drilled faster than with rotational methods |

Complex 3D hole geometry is possible |

Enhanced ease of use and safety due to zero torque and reduced axial load requirement |

Non-Round holes allow a single hole to do the work of two or more |

This „Verdrehsicher“ (or anti-twisting, torsion-proof fastening) prevents part rotation with only a single hole |